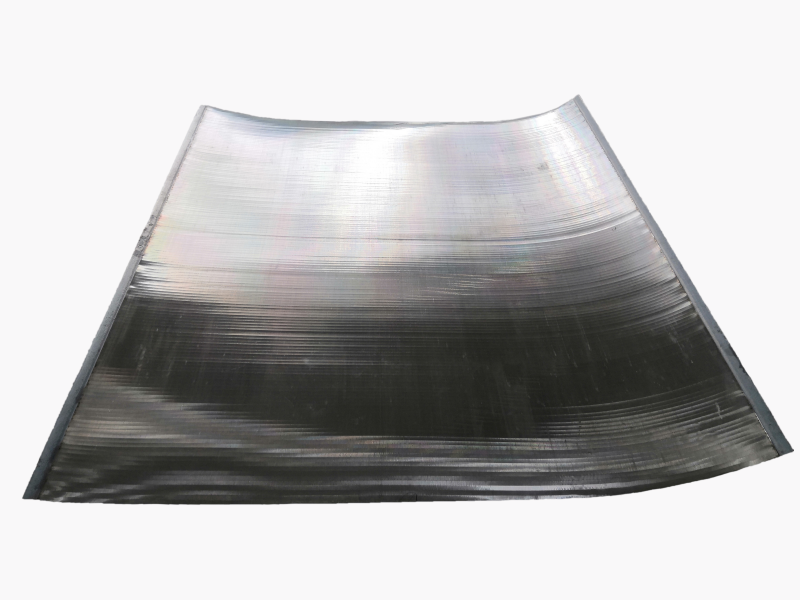

Dewatering Curved Screen

1. The operating noise of our Dewatering curved screen is 85dB(A), which is about 15dB.

2. Our Dewatering curved screen feed section adopts a curved screen surface to improve dewatering efficiency.

3. Our Dewatering curved screen is equipped with a feed box to ensure that materials enter the screen surface evenly.

- YI XIANG

- Anhui, China

- 5 days

- Information

- Download

Introduction of Dewatering curved screen:

Dewatering curved screen is a self-synchronizing heavy-duty equal-thickness screen. Its screen box shape is similar to a banana shape, and the screen beam adopts a box-shaped beam. The transmission system of this vibrating screen consists of a motor passing through a pulley, a V-belt, and then a universal connecting shaft to the exciter. The exciters are connected by an intermediate drive shaft and are commonly used as Coal washing screen plate, Industrial anti-corrosion screen plate, Mineral processing curved screen.

Advantages of High efficiency vibrating screen plate:

1. The Dewatering curved screen is installed horizontally as a whole, but the screen is installed at a negative angle to ensure the effect of forced dehydration. It is often used as a Coal washing screen plate.

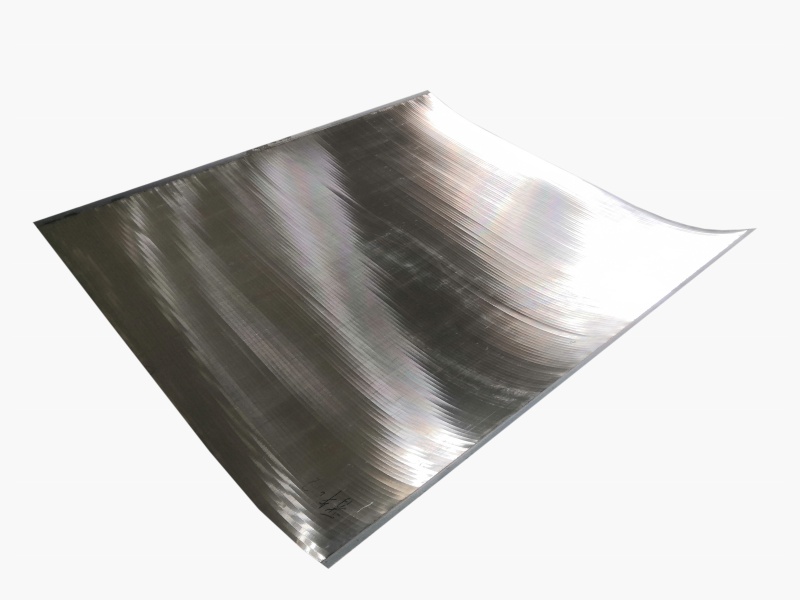

2. Dewatering curved screen can choose stainless steel composite screen plate, tensioned installation, or stainless steel welded slit screen plate, compressed installation, to meet different needs, often used as Industrial anti-corrosion screen plate.

3. The vibration frequency of the Dewatering curved screen can be adjusted at any time through the frequency converter to achieve the best dehydration effect.

4. The Dewatering curved screen is vibrated by a self-synchronizing liquid lubricating vibrator. The screen frame is made of special noise-reducing materials and connected with high-strength bolts to ensure reliable operation of the screen machine and reduce working noise. It is often used as Mineral processing curved screen.

5. Mineral processing curved screen is equipped with an integrated chassis for easy transportation and installation.

6. Industrial anti-corrosion screen plate relies on the filter layer on the screen to intercept fine particles and dehydrate the accumulated material.

Parameters of High efficiency vibrating screen plate:

| Origin: | Anhui, China |

| Brand: | YI XIANG |

| Size: | Accept customization |

| Material: | Stainless steel |

| Delivery time: | 5 days |

Application of High efficiency vibrating screen plate:

Dewatering curved screen has a wide range of applications, such as coal classification, desliming, dehydration, dewatering, etc. It can also be used for screening processing in large-volume material mining operations in mines. It has a simple structure, small floor space, large processing capacity, and almost no power consumption. It is commonly used as Coal washing screen plate, Industrial anti-corrosion screen plate, and Mineral processing curved screen.

Why choose our company:

Our dewatering curved screen has low energy consumption, low noise during operation, and has little impact on the environment. It is an environmentally friendly dehydration equipment. Our company provides professional after-sales service, which can promptly solve users' problems and needs and ensure the stability and long-term operation of the equipment.

About us

Anhui Yixiang Filtration Material Co., Ltd. is located in the Economic Development Zone of Taihe County, Anhui Province. The first phase project covers an area of 30 acres and was put into operation in 2012. The second phase project covers an area of 45 acres and started construction in 2016 with a total investment of US$67 million. The company produces filter materials, and its products are widely used in industry, environmental protection and other fields. The company adheres to the business philosophy of quality first and service first, and is committed to providing customers with high-quality products and services.